No this post is not about plumbing or

smoking. This is about the pipes used in GNU/Linux and other

operating systems.

A Couple of Notes:

This article is about using

redirection, pipes and named pipes in a command shell on a system

running GNU/Linux. If you are not interested in command line use, or

if you are not interested in using GNU/Linux, please do not bother to

make comments about your lack of interest in such things. Comments

about how much better other operating systems are, or how outdated

command line mode is, will not be posted. I am familiar with, and

use, many operating systems. This will not become a forum for arguing

the benefits of other operating system. If you want to post a comment

that describes a similar method of piping input or output for other

operating systems, feel free. Keep it civil and on topic.

Many of the everyday electronic items

we now use are running some form of open source software. This allows

the system to be modified as desired, or needed, by the user. Most

often I find that these items are running a version of GNU/Linux.

Anytime I get a new electronic device, I check to see what operating

system is running, and what access methods are available

Back to the Pipes:

There are three primary methods to

change the standard input, named stdin, and standard output, named

stdout, that are commonly used in GNU/Linux operating systems. These

are redirection, pipes and named pipes. Is redirection a pipe or is a

pipe redirection? In most articles, they consider a pipe to be

redirection. I believe that redirection using the < or >

symbols is a one way pipe. You are piping the input or output of the

command to something other than stdin or stdout. However, in most

cases, you will see the use of < or > referred to as

redirection and the use of | or a named pipe FIFO referred to as a

pipe. I follow that convention most of the time. However, I call

redirection a pipe more often than I call a pipe redirection.

Many text mode commands have default

output and input devices. Often the default output device is stdout

and this is usually directed to the screen, or a window on the

screen. The default input device is usually stdin and is most often

the keyboard. Both of these, as well as another device, called

standard error or stderr, can be redirected to other devices

including files or printers.

In our example below, the file

/tmp/pipe1, is a named pipe FIFO. Output to it is from the Cat

command using a redirection with the > symbol. The default output

device for the cat command is stdout so our use of the redirection

simply changes the output device to the file, which happens to be a

FIFO. This redirection is the first pipe in the example command line.

The second pipe used in the example

below is referred to as, simply enough, a pipe and is designated by

the vertical bar symbol. The normal function of a pipe is to connect

the stdout of the command to the left, to the stdin of the command to

the right. It also causes both commands to run at the same time.

However, not all commands, by default, accept their input from stdin

or send their output to stdout. Ftpput, as used in the example, is

such a command. Ftpput does not have a default input device, it must

be given an input file or device. More on that in a minute. We still

want the Ftpput command to run at the same time as the cat command.

The pipe is being used to make that happen.

As mentioned above, not all programs,

or commands, have a default input or output. Some, such as ftpput,

must be given a file or device to get input from or send output to.

In some cases stdin and stdout can still be used. For example, the

ftpput command will accept input from stdin two different ways.

First, the - symbol can be used in place of the input file name. The

- symbol is used by many programs to represent stdin or stdout,

depending on where it is used in the command line. In the example, we

could use this command line instead of the one given:

#cat (20130908_1916_R*)|ftpput -v

-u(user name) -p(password) (192.168.1.203) ("/Home

Public/Shows/Actual Show Name and Episode.mpg") -

And it will work fine. In this case,

the output from the cat command is being allowed to go to stdout and

the input to ftpput is from stdin. The pipe is creating the link to

redirect stdout and stdin. In other cases, stdout can be given as a

named file with /dev/stdout and stdin can be given as a named file

with /dev/stdin. So the command line:

#cat

(20130908_1916_R*)>/dev/stdout|ftpput -v -u(user name)

-p(password) (192.168.1.203) ("/Home Public/Shows/Actual Show

Name and Episode.mpg") /dev/stdin

Will also work.

With either of these alternate command

lines, the shell simply creates a FIFO in a buffer and uses it in the

same manner as a named pipe FIFO is used.

The third pipe in the example is the

FIFO, /tmp/pipe1, which is known as a named pipe. This is a special

type of file. It is shown in the directory listing with a p, for

pipe, in the first position of the attribute field, the same place

that shows a d for a sub-directory. On some operating systems, the

directory listing will have the vertical bar symbol at the end of the

file name to indicate that the file is a pipe. Using this file, all

data that must, or can, be written to or read from a named file may

be piped from one command to another command. This type of pipe has

some other unique properties besides the name. The file really only

exists in the physical realm as a memory buffer and a name in a

directory. A directory listing will always show the file as having

zero bytes. This is because the file does not accept input from the

command doing the writing, until there is a command running that is

reading the file. Each byte written to the file is expected to be

read right away by another process. The FIFO will cause blocking on

one side if the other side is not running. So the cat command will

wait for the ftpput command to start looking for data before it

starts writing that data.

You may wonder why a named pipe would

be used if the same thing can be accomplished using one of the

alternate methods of redirection of stdin and stdout. That brings us

to another unique property of named pipes. The process, or command,

that is writing to the FIFO and the process that is reading from the

FIFO do not have to be running in the same shell, or even on the same

machine. The example could be broken up so that the cat command is

running in one shell terminal and the ftpput command is running in

another shell terminal. And the terminals do not have to be on the

same machine as long as both have access to the named pipe file and

the operating system on both machines recognize that type of file.

Named pipes are persistent so they

remain after the processes that are using them end. So the /tmp/pipe1

file in the example remains even after the Cat and Ftpput commands

complete and the Telnet session is closed. This is another feature

that can be used by programs. it is possible to have a command

watching the FIFO that will perform a function when the FIFO is

opened by another program or command for data to be written. For

example, I have a script that runs all the time on one of my NAS

units. It watches a FIFO and sends the data it receives to a file

whose name increments each time the command runs. That program

receives data from an automatic backup in a program that could only

be given a single fixed name for the backup file. Before I started

using the FIFO, I had to run a script that renamed all the prior

backup files so the fixed name could be used without overwriting the

past backup.

There are some other interesting

features provided by named pipes. For example, you can read and write

to them from multiple programs at the same time. That allows use of

things like the Tee command which would allow writing the output to

the screen and a file, or to multiple files, at the same time.

This is not intended to be a full Howto

for redirection and pipes. I strongly suggest you explore some of the

excellent information available on the Internet to learn more about

them and how to use them in scripts and programs. This was just an

intro to show how I used all three types to accomplish the goal for

this case.

The Details and Example:

A little background on what I needed to

do and how I did it for this case. Note that I do not use this

command line anymore. I have written a shell script that looks for

new files on the FAT32 partition and does the cat and ftpput

automatically when a new file appears using a database that I created

that contains the date and time the file was copied to the partition

and the name of the show as I want it stored on the NAS drive.

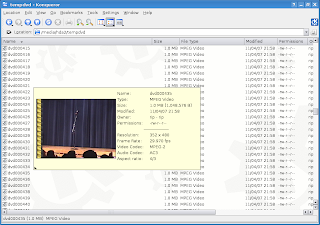

One of my recent purchases was a new,

old stock, DVR device. It was made in 2008 and connects to a network

using a wired or wireless Ethernet connection. I found it was capable

of a Telnet connection and was running a Linux Venus operating

system, a common system for media devices.

This DVR has the capability to copy

recorded programs, which are on a UDF file system, to a hard drive.

However, it will only copy to a FAT32 partition and it breaks the

program up into multiple files, each 2GB, or less. The files are

broken up using a Split command, so to use them on other devices they

must be put back together. I wanted to save these recordings on

network attached storage units, which are formatted as NTFS or EXT3,

so they could be viewed from other attached media devices on the

network Both of those file systems handle files much larger than the

combined file size of any recording. So I just needed to combine the

smaller files into one file on the NAS unit.

The other problem was that the DVR gave

the files names based on the date and time they were copied to the

FAT32 partition. For example, a 3 hour show would have a name, on the

FAT32 drive, like 20130908_1917_Rnn.mpg. The Rnn would be R00, R01

and R02 for the three files the program was split into. I wanted the

actual name of the show to be the final name on the NAS.

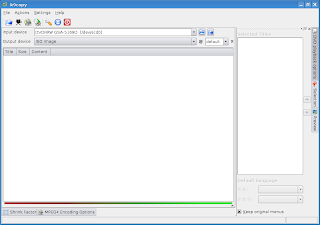

Checking the available commands on the

DVR through a Telnet connection, showed that the only method to get a

file to a NAS drive was using a Ftpput command. There was no Mount

command that could be used to mount a remote share and there was no

standard FTP command that would allow wildcard copies. So the copy to

the NAS would need to be a single file at a time. I would then need

to combine the files on the NAS drive and rename the resulting file.

Without using redirection and pipes, this would require dealing with

each bit of data at least three times on the network.

Here was the solution I decided to use

instead:

I opened a Telnet session to the DVR.

After logging in and changing to the directory where the DVR saved

the copied files, I issued the following command in the shell.

Note: This is the example referred to

above;

#mknod /tmp/pipe1 p;cat

(20130908_1916_R)*>/tmp/pipe1|ftpput -v -u(user name) -p(password)

(192.168.1.203) ("/Home Public/Shows/Actual Show Name and

Episode.mpg") /tmp/pipe1

The ( and ) symbols in the command line

shown are not typed into the actual command line. They are used here

to indicate items that would need to be changed to match the actual

items on your system. For example, your user name and password on the

NAS unit you are copying to. However, the " symbols were needed

since the path and file name have spaces in them..

The Mknod command was used to create

the named pipe FIFO file /tmp/pipe1. On newer GNU/Linux systems a

Mkfifo command is frequently available for this. This system did not

offer that command. The p after the file name tells Mknod that the

file is going to be a named pipe FIFO. As noted earlier, this file is

persistent, so that command does not really have to be run each time.

However if the file exists, the command simply presents a message to

that effect and the shell continues with the next command.

For those who are not familiar with

this, you will notice a semicolon after the Mknod command. The

semicolon tells the shell to run the Mknod command and, when it

finishes, to run the Cat command. This is in contrast to the vertical

bar symbol used between the Cat command and the Ftpput command which

tells the shell to run both commands at the same time.

Next, a Cat command is used to

concatenate the multiple files into a single file using redirection

to the FIFO /tmp/pipe1. The Cat command simply reads the file(s), in

order, and creates an output which is normally directed to stdout.

Redirection of stdout to a file is done using the > symbol. It can

also be redirected using a standard pipe with the | symbol. For

example "cat sometext.txt|more" would cause Cat to read the

file sometext.txt and send it to the More command so it is displayed

one page at a time in the console.

The Cat command and the Ftpput command

are tied together with a standard pipe so they will run at the same

time. Doing this causes the Cat command to open the FIFO for writing

and the Ftpput command to open the FIFO for reading at the same time.

As data is written to the FIFO by Cat, it is read by Ftpput and sent

to the remote file system as a single file. When the Cat command

completes, it closes the FIFO for writing. The Ftpput command will

see that the FIFO has been closed and, once all data has been

processed, will close the file for reading and exit.